How Spinner II Centrifuges Operate

Spinner II centrifuges are typically self-powered (pump-assisted units are also available). They spin at 4000 to 10000 rpm creating fluid pressure sufficient to generate centrifugal force 2000 to 3000 times greater than gravity. This force extracts solid contaminants from the fluid stream and deposits them in the cleanable rotor as a dense, solid cake.

Spinner II centrifuges are highly efficient, self-contained, fluid cleaning units for bypass and off-line filtration of engine lubricants, gear oils, machining fluids, hydraulic oils, quench oils and other industrial fluids. Using the power of centrifugal force, they remove both large contaminants and ultra-fine particles as small as one-tenth of a micron. In a broad range of applications, Spinner II centrifuges are proven to reduce critical component wear up to 50%*. They also meet the challenge of new, low-emissions engines by providing the efficiency to control increased soot loads.

Benefits For You –

REDUCES COSTS

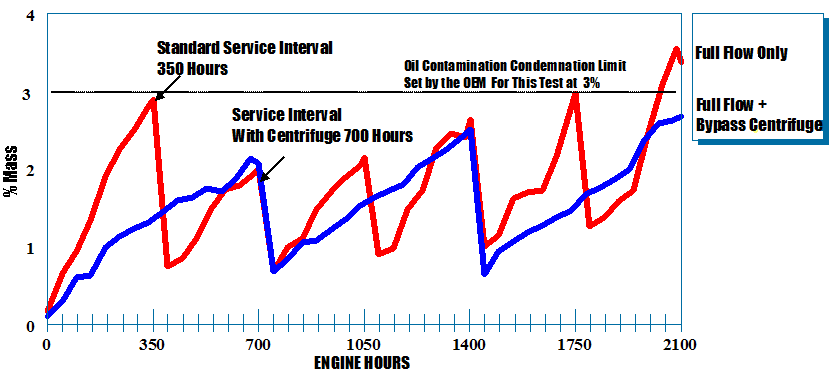

- Extends oil life

- Lengthens service intervals

- Preserves additive potency

- Prolongs full-flow filter life

- Reduces maintenance costs

- Cuts waste disposal costs

- Maximizes in-service time for trucks

- Helps ensure clean combustion and fuel efficiency

- Long-term preventive maintenance

PROTECTS YOUR ENGINES

- Maintains cleaner oil

- Reduces engine wear up to 50%

- Increases engine life

EASY TO MAINTAIN

- Simple, convenient installation

- Fast and easy to service

- No replacement elements

- Contaminant access for engine troubleshooting

BETTER FOR THE ENVIRONMENT

- Reduces oil and filter waste

- Promotes clean combustion and lower emissions

FIELD-PROVEN

- More than a million units in operation in fleets of all sizes

- Standard equipment for more than 40 engine manufacturers worldwide