NEW – Muster II Wire Detection System

Introducing a new level of innovation for the fire suppression market with the release of our new range MusterII. It combines some of the latest technologies with a simple yet innovative design, incorporating plug & play installation.

This new valve is coupled with MusterII’s versatile new alarm panel which monitors system pressures every second. The systems continuous monitoring service is ensured by its own standalone power supply.

The MusterII Fire Suppression System is a true innovation designed for the punishing environment in which machinery operates, helping to manage your risks and protecting your people and assets.

The new MusterII system introduces a higher quality product with greater accuracy and performance.

The complete system is manufactured in stainless steel ensuring its suitability to harsh operating environments, across many industrial and automotive applications.

Loss of Pressure Detection and Automatic Actuation (LOP)

LOP Automatic actuation is the more common form of Fire Suppression Actuation mainly due to confidence in the concept and the lower cost, however if not installed to ensure zero leakage is achieved it can occasionally result in systems actuating when no fire present. To address this concern an alternative MUSTER LOP system is now also available.

Under the standard LOP system, loss of pressure sensing is made of 6mm thermoplastic tubing and is stable to 100°c. The tubing is strategically positioned above areas identified in the risk assessment as being fire risk and requiring fire detection. The tubing is pressurised and when the tubing is exposed to fire the rapid elevation in temperature causes the material to plasticize and rupture. The resulting sudden release of pressure to the actuation circuit then acts to open the actuation valve and release the foam mix. The pressure drop in the system then sets off the fire alarm.

Rise of Pressure Detection and Automatic Actuation (ROP)

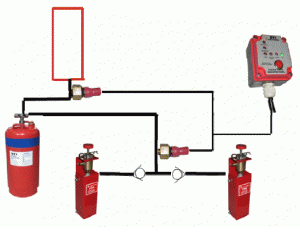

In the event of a fire, the system will automatically activate via the use of two fire detectors/actuators.The detectors are made from 12.7mm stainless steel and can be shaped to fit the intended environment above the fire hazard.

The detectors come complete with filter assembly and check valve for connection to a manifold. These detectors/actuators contain a chemical core that, when a sustained temperature of over 175 degrees Celsius is reached, it automatically sends a pressure pulse through the actuation system to the cylinder valve, via the check valve manifold, to release the foam. At the same time, a pressure switch mounted on the manifold trips and notifies the alarm panel, thereby alerting the operator.

As this product is subject to a specific expiry time, replacement tubes containing the chemical are made available. These replacement tubes do not come with the filter assembly or the check valve.

Muster – Fire Extinguisher Products

Introducing the new range of MUSTER Fire Extinguishers that are available in various models and sizes, which are designed to quickly control and extinguish flames, The MUSTER range of Fire Extinguishers was introduced by JSG Industrial Systems to compliment the range Muster Fire Suppression Systems, protecting machinery and personnel while reducing the risk of OH&S incidents.

The range Muster of Fire Extinguisher’s include:

- Portable

- Mobile

- Automatic

- Fire Blankets

The extinguisher mediums used in the Muster Fire Extinguisher’s are:

- Carbon Dioxide (CO2)

- Foam (AFFF)

- Air/Water

- Wet Chemical (Fire Extinguisher Solution)

- Dry Powder (ABE Dry Chemical Powder)